LE ROQUEFORT VERNIERES Frères

Le Terroir

Le roquefort, roi des fromages et fromage des rois, est né en plein cœur des magnifiques paysages de l’Aveyron dans le sud de la France.

La famille Vernières, propriétaire de caves depuis le XVe siècle à Roquefort est encore l’un des grands Ambassadeurs de ce pays, de ce terroir.

Cette fromagerie familiale a su garder sa totale indépendance « fabriquer et commercialiser » son protégé tout en cultivant l’amour de son produit. Choyant chaque étape de sa fabrication, elle améliore et transmet son savoir-faire ancestral de générations en générations, tout en utilisant les technologies les plus avancées afin d’optimiser son élaboration.

Le Lait de Brebis

Le Roquefort Vernières est fabriqué exclusivement avec du lait de brebis de race Lacaune spécialement choisie pour son aptitude laitière alliée à une rusticité adaptée à nos rudes plateaux Caussenard et du Lévezou.

Du 15 novembre au 31 juillet, la traite est effectuée 2 fois par jour pour une production moyenne de 2 litres par brebis.

Nos 53 producteurs se situent sur le plateau du Lévezou entre 700 et 800 mètres d’altitude, et pour conserver au lait toutes ses qualités, il est collecté frais chaque matin en camion-citerne isolée.

La densité de notre zone de collecte ne fait qu’aucun de nos producteurs n’ait éloigné de plus de 20 km de notre fromagerie.

La Fabrication

Comme l’exige la loi du 26 Juillet 1925 qui définit l’appellation Roquefort et le protège, le lait est traité pur et entier, sans aucun écrémage ni pasteurisation. Cette contrainte ajoutée au fait que l’on travaille un lait cru exige du fabricant une attention de tous les instants, en raison de l’hétérogénéité de la matière première, ce qui implique un contrôle journalier des laits individuels dès leur arrivée à la fromagerie.

Un échantillon prélevé dans le tank du producteur, est contrôlé chaque jour dès réception dans notre laboratoire.

Les résultats doivent être conformes d’une part au cahier des charges établi par l’Interprofession qui a déterminé les critères généraux de conformité pour répondre aux règles de l’AOC, et d’autre part aux critères spécifiques déterminés par notre fromagerie.

Après vérification de la température, le lait est mélangé, refroidi et mis en attente pour la fabrication du fromage. Le lait réchauffé à 32°C arrive dans les cuves de fabrication conçues spécialement pour le roquefort. Elles garantissent la meilleure technologie possible et l’hygiène optimum du produit.

La spécificité de notre Roquefort Vernières est assurée par le choix des souches sélectionnées de Penicillium Roqueforti ainsi que par les préparations de flore lactique utilisées en complément du lait cru. Après l’apport de la présure, commence la coagulation.

Au bout de 2 heures environ et à l’appréciation du maître fromager, le travail en cuve commence. Son expérience, son métier déterminent les diverses opérations à effectuer, le lait cru demandant une adaptation technologique quotidienne et variée.

Ce travail très important sera l’un des éléments déterminant la conformité du produit, et conditionnant fortement sa qualité gustative future.

Dans une ambiance à 17°, le fromage continue à prendre forme.

Il perd son excès d’eau, et commence à recouvrer son identité. Un marquage indélébile lui est appliqué et le suivra jusqu’à votre table.

Après salage à sec, loi et tradition respectées, le sel de mer permet la protection du produit, jusqu’à sa consommation tout en préservant le goût typique de ce fromage de caractère.

Avant son départ pour le village de Roquefort, le fromage est aéré, permettant ensuite au pénicillium roqueforti de bien se développer dans l’ambiance des caves.

Les Caves de

Roquefort Vernières Frères

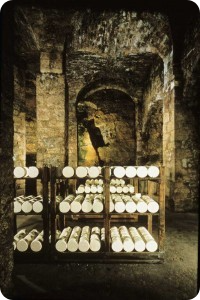

Deux caves permettent l’affinage de 1300 tonnes de fromages, sur une période allant du 1er décembre au 30 juillet, correspondant à la collecte et la fabrication.

Les caves à Roquefort sont naturelles. Un éboulis du plateau du Combalou, surplombant le village, a fait naître des failles : « Les Fleurines ». L’air parcourant les fleurines détermine la température et l’humidité de ces caves et donc leur spécificité.

Une bonne cave est très humide et la température y est constante.

Le maître affineur détermine le moment où le fromage est prêt à quitter la cave pour recevoir son emballage protecteur (une feuille d’étain pur). Le fromage est ensuite stocké à l’abri de l’air, de la lumière et de la chaleur.

Il ne doit pas être expédié avant 3 mois d’âge minimum (AOC).

Avant la vente, le fromage est déshabillé de son emballage protecteur.

Il est lavé simplement à l’eau claire. La croûte doit être propre. Il est séché.

Notre gamme comprend des tranches, des portions, des ½ pains et des mini dés. Diverses machines conditionnent tous ces produits dans des conditions d’hygiène optimales.

Notre souplesse d’adaptation nous permet de livrer aussi bien le marché Français que le marché export avec le respect de toutes leurs spécificités.

Tous les lots de fromages sont analysés et ne seront expédiés que s’ils sont conformes à la législation et au cahier des charges des clients.

Chaque carton est identifié suivant un code interne qui permet d’assurer le suivi jusqu’à la consommation.

Le respect des règles d’hygiène, les locaux neufs, la formation et le savoir-faire permettent de vous garantir un produit de qualité récompensé par une certification BRC, des plus exigeantes. C’est ainsi que le Roquefort Vernières, bijou du terroir et du savoir-faire des hommes, se déguste légèrement chambré, seul, en famille ou entre amis.

Roquefort Vernières Frères de A à Z

Le roquefort, roi des fromages et fromage des rois, est né en plein cœur des magnifiques paysages de l’Aveyron dans le sud de la France.

La famille Vernières, propriétaire de caves depuis le 15ème siècle à Roquefort est encore l’un des grands Ambassadeurs de ce pays, de ce terroir.

Cette fromagerie familiale a su garder sa totale indépendance « fabriquer et commercialiser » son protégé tout en cultivant l’amour de son produit.

Choyant chaque étape de sa fabrication, elle améliore et transmet son savoir-faire ancestral de générations en générations, tout en utilisant les technologies les plus avancées afin d’optimiser son élaboration.

Le Roquefort Vernières est fabriqué exclusivement avec du lait de brebis de race Lacaune spécialement choisie pour son aptitude laitière alliée à une rusticité adaptée à nos rudes plateaux Caussenard et du Lévezou.

Du 15 novembre au 31 juillet, la traite est effectuée 2 fois par jour pour une production moyenne de 2 litres par brebis.

Nos 83 producteurs se situent sur le plateau du Lévezou entre 700 et 800 mètres d’altitude, et pour conserver au lait toutes ses qualités, il est collecté frais chaque matin en camion-citerne isolée.

La densité de notre zone de collecte ne fait qu’aucun de nos producteurs n’ait éloigné de plus de 20 km de notre fromagerie.

Un échantillon prélevé dans le tank du producteur, est contrôlé chaque jour dès réception dans notre laboratoire.

Les résultats doivent être conformes d’une part au cahier des charges établi par l’Interprofession qui a déterminé les critères généraux de conformité pour répondre aux règles de l’AOC, et d’autre part aux critères spécifiques déterminés par notre fromagerie.

Après vérification de la température, le lait est mélangé, refroidi et mis en attente pour la fabrication du fromage. Le lait réchauffé à 32°C arrive dans les cuves de fabrication conçues spécialement pour le roquefort. Elles garantissent la meilleure technologie possible et l’hygiène optimum du produit.

La spécificité de notre Roquefort Vernières est assurée par le choix des souches sélectionnées de Penicillium Roqueforti ainsi que par les préparations de flore lactique utilisées en complément du lait cru. Après l’apport de la présure, commence la coagulation.

Au bout de 2 heures environ et à l’appréciation du maître fromager, le travail en cuve commence. Son expérience, son métier déterminent les diverses opérations à effectuer, le lait cru demandant une adaptation technologique quotidienne et variée.

Ce travail très important sera l’un des éléments déterminant la conformité du produit, et conditionnant fortement sa qualité gustative future.

Dans une ambiance à 17°, le fromage continue à prendre forme.

Il perd son excès d’eau, et commence à recouvrer son identité. Un marquage indélébile lui est appliqué et le suivra jusqu’à votre table.

Après salage à sec, loi et tradition respectées, le sel de mer permet la protection du produit, jusqu’à sa consommation tout en préservant le goût typique de ce fromage de caractère.

Avant son départ pour le village de Roquefort, le fromage est aéré, permettant ensuite au pénicillium roqueforti de bien se développer dans l’ambiance des caves.

Les caves à Roquefort sont naturelles. Un éboulis du plateau du Combalou, surplombant le village, a fait naître des failles : « Les Fleurines ».

L’air parcourant les fleurines détermine la température et l’humidité de ces caves et donc leur spécificité. Une bonne cave est très humide et la température y est constante.

Le maître affineur détermine le moment où le fromage est prêt à quitter la cave pour recevoir son emballage protecteur (une feuille d’étain pur). Le fromage est ensuite stocké à l’abri de l’air, de la lumière et de la chaleur.

Il ne doit pas être expédié avant 3 mois d’âge minimum (AOC).

Avant la vente, le fromage est déshabillé de son emballage protecteur.

Il est lavé simplement à l’eau claire. La croûte doit être propre. Il est séché.

Notre gamme comprend des tranches, des portions, des ½ pains, des mini dés. Diverses machines conditionnent tous ces produits dans des conditions d’hygiène optimales.

Notre souplesse d’adaptation nous permet de livrer aussi bien le marché Français que le marché export avec le respect de toutes leurs spécificités.

Tous les lots de fromages sont analysés et ne seront expédiés que s’ils sont conformes à la législation et au cahier des charges des clients.

Chaque carton est identifié suivant un code interne qui permet d’assurer le suivi jusqu’à la consommation.

Le respect des règles d’hygiène, les locaux neufs, la formation et le savoir-faire permettent de vous garantir un produit de qualité récompensé par une certification BRC, des plus exigeantes.

C’est ainsi que le Roquefort Vernières, bijou du terroir et du savoir-faire des hommes, se déguste légèrement chambré, seul, en famille ou entre amis.

Label Brebis Rouge

Depuis 1930, le Roquefort bénéficie du « label brebis rouge » qui réglemente la nourriture des brebis : fourrage et céréales en hiver, pâturage le reste du temps. A noter également que le lait provient uniquement de brebis de race Lacaune.

Ce label est une marque collective créée en 1930 par la Confédération des Producteurs de Lait de Brebis et des Industriels de Roquefort. Il certifie l’origine et la qualité du Roquefort dans le monde entier.

L'AOP Roquefort

Les appellations d’origine protégées sont nées d’une réglementation européenne de 1992 qui vise à protéger toutes les AOC au niveau de la Communauté en leur maintenant leurs cahiers des charges qui s’imposent, désormais, aux autres Etats de l’Union, particulièrement au niveau géographique. Les AOP permettent de conserver un lien étroit entre les AOC et le terroir où elles sont produites.

Bien sûr, toutes les AOC fromagères françaises sont aussi des AOP.

La loi régissant le principe de l’AOC est votée en France en 1919.

La première AOC fromagère française a vu le jour par une loi de Juillet 1925 : le Roquefort.

C’est en 1935 qu’une loi fixe cependant les caractéristiques des fromages (composition, MG, lait) ; en 1941, le poids et l’extrait sec sont réglementés ; en 1947 et depuis chaque fromage postulant à l’appellation détermine un cahier des charges de l’éleveur aux distributeurs, permettant de protéger ceux qui ont investi dans cette démarche.

Décrets AOC ROQUEFORT 22 01 2001